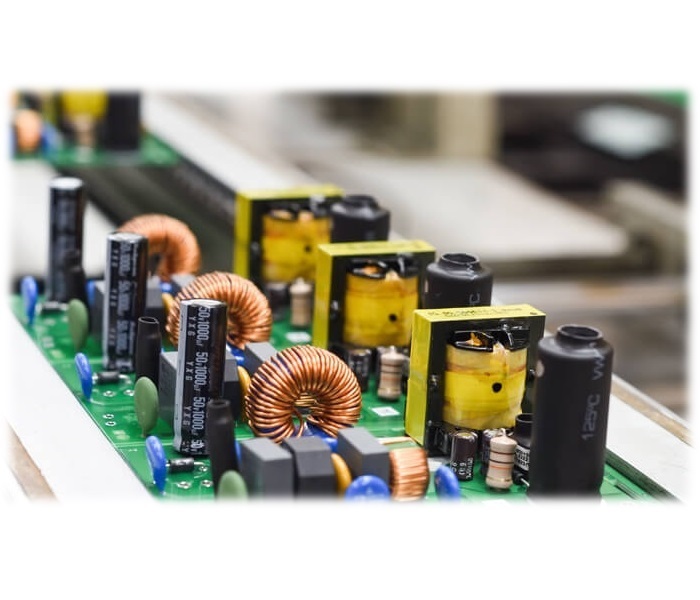

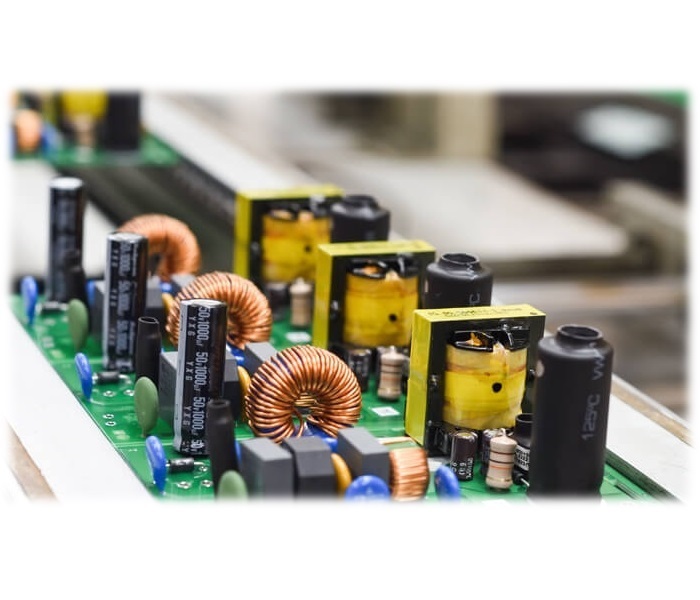

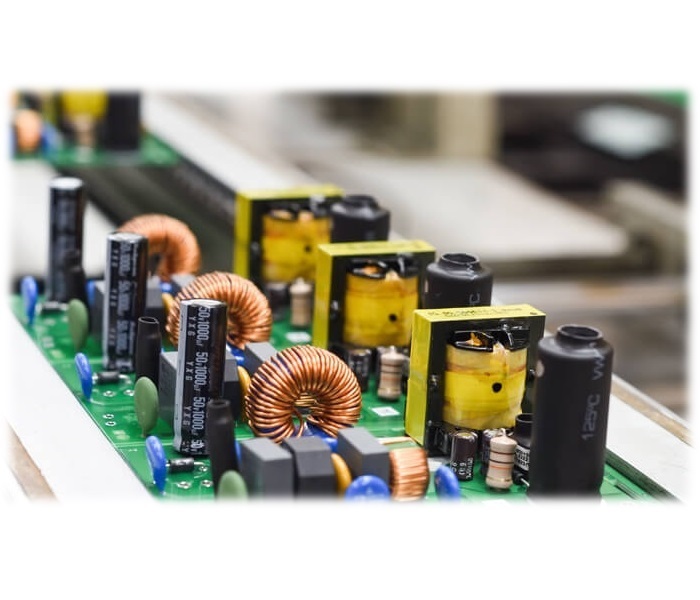

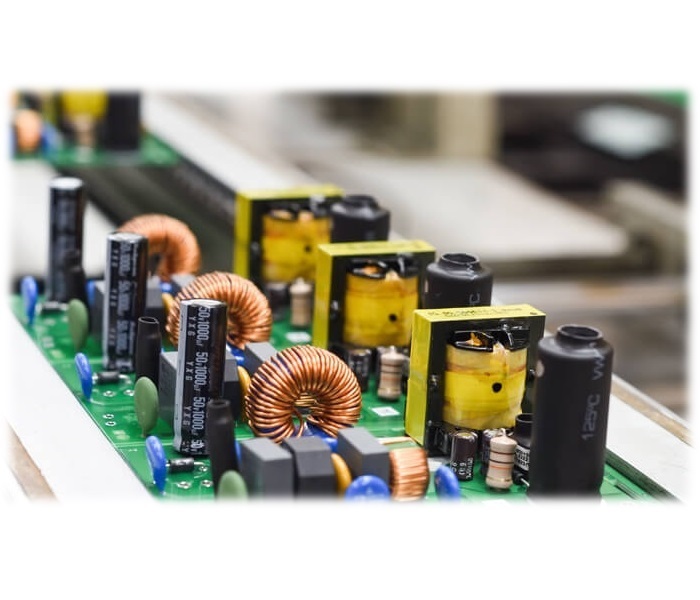

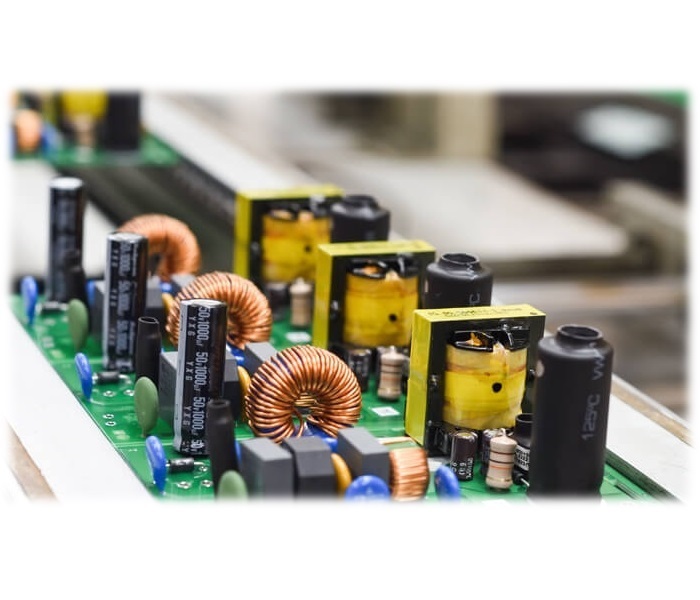

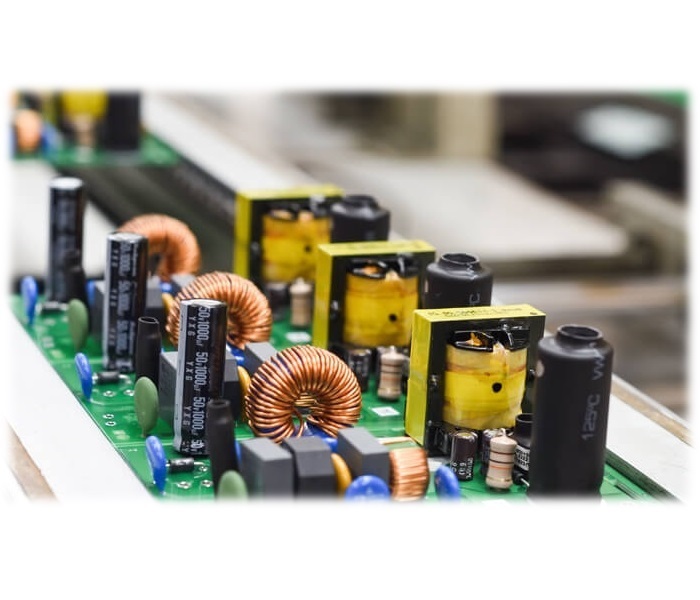

PCB Assembly is one of the most challenging steps of any Electronics Product Design. The layout and design of your PCBA is the sole driving force behind product performance and safety. The number of electronic devices that require PCBA is increasing at an exponential rate. User demand, increased functionality requirements and shrinking device sizes are driving a surge in the demand for PCBAs. Our EMS team offers Through Hole (THT) or Surface Mount Technology (SMT) or a mix of both, to place variety of components onto the PCB as per of the client requirements.

Creatons has a state-of-the-art set up in Noida, Delhi NCR to offer PCB Assembly services quickly, efficiently and cost effectively. We have a multi-floor facility that hosts the latest infrastructure – Latest CO2 Laser Marking Machines, Automatic & Semi-Automatic Printers, Panasonic Mounters, Koh Young SPI Machines, Jutze AOI Machines, JT Reflow Ovens, Getech Routers, Stencil Cleaning Machine, X-Ray Machine, Conformal Coating Machine, Wave Soldering Machine, Whitt Conveyors & the best team of qualified professionals with the latest technical knowledge in PCB Assembly Services. Our experts believe in continual improvements, be it processes, or quality procedures or testing parameters, thus ensuring top-class deliveries every time.

It’s a fully automatic laser marking machine for marking 1D, 2D, QR Code, Text, Symbol or Graphic on the surface PCB. Embedded with USA made SYNRAD laser head, it offers XY high precision motion platform, repeatable positioning accuracy of ±0.025mm via its CCD visual system, conveyor with automatic width adjustment and camera online barcode reading system.

It’s a high-performance quality stencil screen printer, for Accuracy it has built-in ±8micron alignment, and ±15micron wet print repeatability (≧2.0Cpk@6sigma) with 7 seconds total throughput, included print and stencil cleaning cycles. And accommodates PCB board from 50*50mm to 500*460mm, a 2 minutes product changeover time, and a new product set up time in 5 minutes.

It’s a high-performance quality stencil screen printer, for Accuracy it has built-in ±8micron alignment, and ±15micron wet print repeatability (≧2.0Cpk @ 6sigma) with 7 seconds total throughput, included print and stencil cleaning cycles. And accommodates PCB board from 50*50mm to 500*460mm, a 2 minutes product changeover time, and a new product set up time in 5 minutes.

KY8030 delivers faster inspection without compromising performance and accuracy. Using patented dual projection, the system eliminates the critical Shadow problem that all 3D SPI systems can be vulnerable to. Easy UI and SPC Plus are included in the system package in order to help users achieve faster & easier printer process optimization.

Panasonic NPM-D3A is an industry standard building block in high-speed, high volume applications ranging from automotive to consumer electronics to medical. With compact dual-beam, NPM-D3A offers a reinforced frame, advanced head, and award-winning Multi Recognition Camera to improve placement accuracy down to 30um. Based on this, our one SMT line is capable of achieving a maximum CPH of 6,44,000.

Panasonic NPM-D3A is an industry standard building block in high-speed, high volume applications ranging from automotive to consumer electronics to medical. With compact dual-beam, NPM-D3A offers a reinforced frame, advanced head, and award-winning Multi Recognition Camera to improve placement accuracy down to 30um. Based on this, our one SMT line is capable of achieving a maximum CPH of 6,44,000.

Known for high speed and high precision, Jutze AOI is widely used in the production lines of smart devices such as Smartphones, Laptops, Tablets, IT Hardware, Medical Devices and Automotive. Embedded with multi-channel light source and High-speed multi-frame camera, it processes multiple photos at a time to offer most powerful detailed optical analysis of the pcba running online.

Industry 4.0 Ready, JTU Reflow Ovens offers stable & repeatable profiles. Independent Air Velocity Control and Temperature Controlling System provides flexible process control to easily handle various complex soldering requirements. Due to its longer heating zones, it delivers higher production efficiency and better throughput. It’s advanced flux management and cooling system with dual independent heat exchangers offers maximum cooling effect. It’s larger aluminum alloy heat plates helps to lower down the power consumption and carbon emission.

Industry 4.0 Ready, JTU Reflow Ovens offers stable & repeatable profiles. Independent Air Velocity Control and Temperature Controlling System provides flexible process control to easily handle various complex soldering requirements. Due to its longer heating zones, it delivers higher production efficiency and better throughput. It’s advanced flux management and cooling system with dual independent heat exchangers offers maximum cooling effect. It’s larger aluminum alloy heat plates helps to lower down the power consumption and carbon emission.

The GSR1200 is a standalone router machine specially designed to de-panelize panels of up to 350mm x 350mm into individual units. The superior servo axis system provides high acceleration/deceleration, reducing cycle time and at the same time maintaining high accuracy cutting. Using a high-resolution CCD camera, and GSR user-friendly Windows-based software allows the user to program the routing paths in minutes. All the axes and linear guides used are protected from dust and dirt to increase lifespan and performance.

We use customized motorize conveyor solution for taking care of the manual insertion of various type of components onto the bare PCB’s. After manual insertions, PCB’s goes into the wave soldering process following up with touch ups and quality inspection and testing processes. Our process and quality team take whatever it takes to deliver the best as per of the client requirements.

We use customized motorize conveyor solution for taking care of the manual insertion of various type of components onto the bare PCB’s. After manual insertions, PCB’s goes into the wave soldering process following up with touch ups and quality inspection and testing processes. Our process and quality team take whatever it takes to deliver the best as per of the client requirements.

Our wave soldering machine employs closed loop with inverter control system to keep the stability and accuracy of the conveyor speed. It uses hot air heating for preheating zones. To ensure uniform flux coating, it uses spray flux system, driven by a stepping motor. It’s modular design is suitable for soldering of both SMT & THT component types. The centrifugal exhaust fan with double filters helps to avoid any flux drop to the PCB’s running online. Built-in forced air cooling system enables to attain the desirable cool down slope.